Substitution (Br)

(N-Heteroaryls)

Examples:

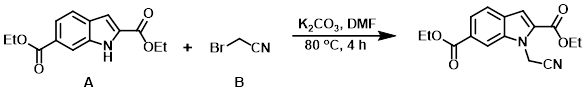

Example 1

To a solution of the indole (A) (6.0 g, 22.9 mmol) in dry DMF (60 mL) was added K2CO3 (9.52 g, 68.9 mmol) and the mixture was stirred under N2 at RT for 30 min. To this mixture was added the alkyl bromide (B) (5.5 g, 45.9 mmol) and the reaction was stirred at 80 C for 4 h. After completion, the reaction mixture was cooled to RT and diluted with EtOAc (50 mL). The mixture was washed with brine (50 mL), then cold H2O (50 mL). The org layer was dried (Na2SO4) and concentrated in vacuo. The resulting material was purified by silica gel column chromatography to provide the product as an off-white solid. [6.0 g, 87%]

[Patent Reference: WO2014149164, page 300, ![]() (23.7 MB)]

(23.7 MB)]

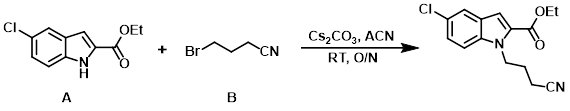

Example 2

The indole (A) (33.55 g, 150 mmol) was dissolved in ACN (600 mL) and stirred at RT. Then Cs2CO3 (73.31 g, 225 mmol) was added and stirring was continued for 30 min. The alkyl bromide (B) (18.83 mL, 180 mmol) was added in small portions over a period of 1 h, then the reaction mixture was stirred at RT overnight. The mixture was filtered and the filtrate was concentrated. The residue was dissolved in DCM and washed with H2O. The org layer was dried (MgSO4) and concentrated to provide the product. [43.5 g, 99%]

[Patent Reference: WO2015158653, page 34, ![]() (2.9 MB)]

(2.9 MB)]

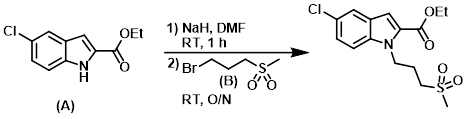

Example 3

The indole (A) (2.3 g, 8.6 mmol) was dissolved in DMF (50 mL). To the stirring mixture at RT was added NaH (60% suspension in mineral oil, 0.52 g, 12.8 mmol). The mixture was stirred at RT for 1h, after which time was added to alkyl bromide (B) (2.6 g, 12.8 mmol). The reaction mixture was stirred at RT overnight. The mixture was poured into ice-H2O and extracted with EtOAc. The org layer was dried (MgSO4) and concentrated to give a crude brown oil. The crude material was purified by column chromatography (MeOH/DCM) to provide the product as a white solid. [3.2 g, 96%]

[Patent Reference: WO2015158653, page 33, ![]() (2.9 MB)]

(2.9 MB)]

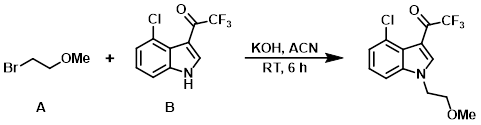

Example 4

To a mixture of the indole (B) (5.00 g, 20.2 mmol) and KOH (1.70 g, 29.8 mmol) in ACN (20 mL) was added the alkyl bromide (A) (4.2 g, 30.4 mmol) at RT. The reaction was stirred at RT for 6 h, then H2O (50 mL) was added. The precipitate was collected by filtration and dried in vacuo to provide the product as a white solid, which was used in the next step without further purification. [6.4 g, 61.2 %]

[Patent Reference: WO2016100281, page 98, ![]() (10.3 MB)]

(10.3 MB)]

Example 5

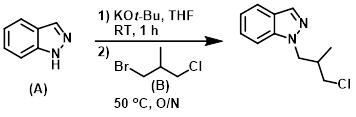

A RBF was charged with the indazole (A) (3.54 g, 30.0 mmol) in dry THF (100 mL). KOt-Bu (3.54 g, 31.5 mmol) was added and the mixture was stirred at RT for 1h. Then the alkyl bromide (B) (3.68 mL, 31.5 mmol) was added and the reaction mixture was stirred at 50 C overnight. The mixture was quenched with H2O and extracted with EtOAc. The combined organics were dried (Na2SO4) and concentrated. The crude material was purified by silica gel column chromatography (1:2 EtOAc/heptane) to provide the product. [4.66 g]

[Patent Reference: WO2014152144, page 54, ![]() (4.6 MB)]

(4.6 MB)]

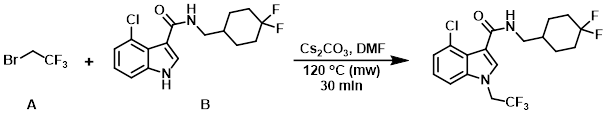

Example 6

A mixture of the indole (B) (0.163 g, 0.50 mmol), the alkyl bromide (A) (0.204 g, 1.25 mmol), and Cs2CO3 (489 mg, 1.50 mmol) in anhydrous DMF (2 mL) was stirred in a microwave reactor at 120 C for 30 min. The reaction mixture was diluted with EtOAc (20 mL) and washed with H2O (3 x 20 mL). The org layer was dried (Na2SO4) and concentrated in vacuo. The residue was purified by Prep HPLC to provide the product as a white solid. [0.067 g, 33%]

[Patent Reference: WO2016100281, page 93, ![]() (10.3 MB)]

(10.3 MB)]

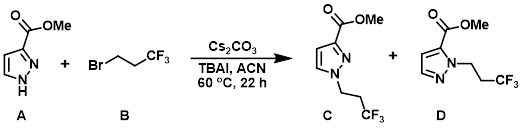

Example 7

The pyrazole (A) (0.500 g, 3.96 mmol) was dissolved in dry ACN (30 mL), then the alkyl bromide (B) (0.507 mL, 4.76 mmol) was added, followed by Cs2CO3 (1.938 g, 5.95 mmol). The reaction mixture was stirred at 60 C for 2 h. Additional alkyl bromide (B) (0.507 mL, 4.76 mmol) was added, followed by TBAI (0.146 g, 0.396 mmol), and the reaction was stirred at 60 C for 14 h. Additional Cs2CO3 (1.938 g, 5.95 mmol), TBAI (0.146 g, 0.396 mmol), and alkyl bromide (B) (0.507 mL, 4.76 mmol) were added, and the reaction mixture was stirred at 60 C for 6 h. The mixture was cooled to RT and diluted with EtOAc. Celite was added and the solvent was removed in vacuo. The residue was purified by flash chromatography (solid loading on celite, 0-55% EtOAc/hexane) to provide the two products. [C, 0.257 g, 29%] [D, 0.228 g, 26%]

[Patent Reference: WO2016010950, page 164, ![]() (18.8 MB)]

(18.8 MB)]