Cbz Deprotection

(H2 + Pd/C)

Examples:

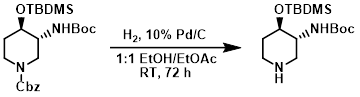

Example 1

To a solution of the SM (1.0 equiv) in 1:1 EtOH/EtOAc (0.1M) was added 10% Pd/C (0.1 equiv). The resulting mixture was stirred under an atmosphere of H2 for 72 h, after which time the mixture was filtered through a celite pad. The celite pad was washed with EtOAc and the filtrate was concentrated in vacuo to provide the product. [99%]

[Patent Reference: WO2010026121, page 65, ![]() (3.6 MB)]

(3.6 MB)]

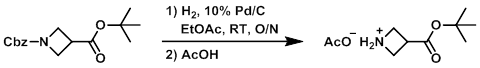

Example 2

A mixture of the SM (140 g, 0.480 mol) and 10% Pd/C (28.0 g) in EtOAc (1.40 L) was placed in an autoclave under 3.0 kg/cm2 of H2 pressure overnight. The reaction mixture was filtered through celite, and the celite bed was washed with EtOAc. To the filtrate was added AcOH (28.9 g, 0.480 mol). The mixture was concentrated in vacuo (maintaining the temp below 50 C) to provide the product as the carboxylate acetic acid salt. [96 g, 92%]

[Patent Reference: WO2011017578, page 127, ![]() (8.3 MB)]

(8.3 MB)]

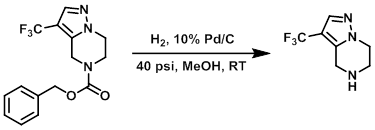

Example 3

To a solution of the SM (7.5 g, 23 mmol) in MeOH (300 mL) was added 10% Pd/C (2 g). The reaction mixture was hydrogenated in a Parr apparatus at RT under 40 psi H2. After H2 uptake ceased, the reaction mixture was filtered and the filtrate was concentrated. The resulting material was recrystallized from hexane to provide the product as a white solid. [2.9 g, 65%]

[Patent Reference: WO2014177977, page 86, ![]() (6.0 MB)]

(6.0 MB)]

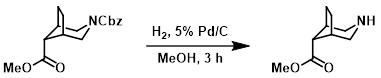

Example 4

A suspension of the SM (0.66 g, 2.2 mmol) and 5% Pd/C (0.10 g) in MeOH (5 mL) was stirred under a H2 atmosphere for 3 h. The mixture was filtered through a pad of celite and the celite pad was washed with 10% MeOH/DCM. The filtrate was concentrated in vacuo to provide the product. [0.34 g, 92%]

[Patent Reference: WO2016014463, page 74, ![]() (6.7 MB)]

(6.7 MB)]