Alkene to Alkane

(H2 + Pd/C)

Examples:

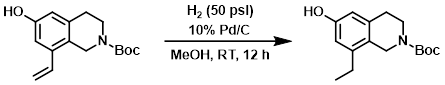

Example 1

A mixture of the SM (7.2 g, 26.2 mmol) and 10% Pd/C (2 g) in MeOH (100 mL) was stirred under an atmosphere of H2 (50 psi) at RT for 12 h. The mixture was filtered through celite and the filtrate was concentrated. The residue was purified by silica gel flash chromatography to provide the product. [5.8 g, 80%]

[Patent Reference: WO2016014463, page 102, ![]() (6.7 MB)]

(6.7 MB)]

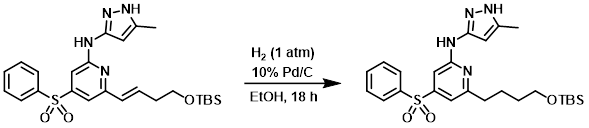

Example 2

To a solution of the SM (290 mg, 0.506 mmol) in EtOH (15 mL) was added 10% Pd/C (30 mg). The system was degassed three times (vacuum/N2), then reacted under H2 (1 atm) for 2h. Additional 10% Pd/C (30 mg) was added, the system was degassed, and the reaction mixture reacted under H2 (1 atm) for another 16 h. The mixture was filtered through a pad of celite and the pad was washed with EtOH (30 mL). The filtrate was concentrated to provide the product as a green oil. [238 mg, 94%]

[Patent Reference: WO2016001341, page 125, ![]() (9.1 MB)]

(9.1 MB)]

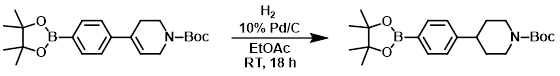

Example 3

A solution of the SM (4.1 g, 10.64 mmol) in EtOAc (60 mL) was treated with 10% Pd/C (dry, 0.5 g). The reaction mixture was stirred under a H2 atmosphere at RT for 18 h. The catalyst was removed by filtration and washed with EtOAc (100 mL). The filtrate was concentrated in vacuo to provide the product as a white solid. [3.4 g, 85%]

[Patent Reference: WO2015088045, page 105, ![]() (10.3 MB)]

(10.3 MB)]

Example 4

To a solution of the SM (34 mg, 0.157 mmol) in THF (3 mL) and MeOH (1 mL) was added TEA (0.11 mL, 0.79 mmol) and 10% Pd/C (16.7 mg, 0.016 mmol) at RT. The reaction mixture was stirred under H2 (balloon) at RT for 1 h. The catalyst was filtered off, and the solvent was removed in vacuo to provide the product. [34 mg, 100%]

[Patent Reference: WO2016010950, page 258, ![]() (18.8 MB)]

(18.8 MB)]